- Services >

- Printing

Printing

-

Digital Printing

Are you looking for smaller quantity runs, variable data, faster run times, or better quality? Look no further than digital printing! We have doubled down on our digital printing capabilities, and the change has been transformative with the service that we are able to provide. The entire customer experience from quoting to prepress, print, and delivery, is new and improved with the new Pittcraft.

Have a unique challenge with your print project, or looking for something to set yourself apart? Give us an opportunity to show you how our digital tool kit can save you time, money, and make your look and feel go from good to great!

-

Offset Lithography

Offset lithography has in general been regarded as being higher quality than digital printing. However, digital printing has made great strides over the past 3-5 years. Consequently, the quality gap between the 2 processes has virtually gone away. In certain situations offset is better and in other situations digital works best. Our job is to help you make that a hassle-free decision.

Our team will evaluate all aspects of your project including quantity, paper type, paper size, finish, turnaround, and budget to recommend the best print process. A network of in-house resources and high-end print partners gives us one of the most robust product offerings in the Midwest.

-

Large Format Printing

If you want to make a statement, the best way to do it is to go big or go home! Our printing capabilities can accommodate all large-format products so that you can deliver your message in a big way. There’s no way your audience will miss what you have to say.

Print Capabilities

We understand from a marketing standpoint, the goal is to ensure your brand stands out. Our custom solutions include specialty finishing options, personalized creative designs, and a start to finish project management effort that will set you apart from competitors and demonstrate your individuality.

Learn more about how we can help you develop a one-of-a-kind project or campaign. Click on any of the links below for more details!

Binding & Finishing

-

Saddle Stitch

Saddle stitched binding is a common binding for magazines, catalogs, and brochures. The pages of the book are bound together with 2 pieces of wire or staples that literally stitch themselves through the pages of the book, and hold them in place.

-

Perfect Binding

Perfect Binding is a widely used softcover book binding method. With this binding method, the pages and cover are glued together at the spine with a strong yet flexible thermal glue. The other three sides of the book are then trimmed as needed to give them clean “perfect” edges.

-

Spiral Binding

Spiral Binding and Coil Binding are interchangeable terms for the same bookbinding method. This popular method joins the pages and cover of a book using a durable plastic or metal coil. The coil is inserted and twisted through small holes or slots punched along the spinal edge of the book's cover and pages.

-

Wire-O Binding

Wire-O binding is a similar process to that of spiral/coil binding but will use a spiraled wire piece instead of the coated coil.

-

Padding/Glueing

Specialty Coatings

-

Spot & Flood Coatings

The term "spot" within the print world refers to the process of applying a specialty coating to a particular spot or shape on the press sheet. This could be a hit of coating on a logo, image, or graphic within a design for that extra pop of wow! The term "flood" within the print world refers to the process of applying a specialty coating to an entire press sheet. This process essentially “floods” the entire sheet of paper so when the piece is trimmed to the final size there is no void of coating anywhere.

-

Dull & Gloss Coatings

The term "Dull" within the coating process of the print world refers to the finish sheen of a coating. Dull and Matte are almost interchangeable, and do not dry with a glossy or shiny look, but more the look of a satin paint after it has dried. In turn "Gloss" within the coating process of the print world refers to the finish sheen of a coating that dries with a glossy or shiny look.

-

Aqueous Coatings

Low-cost water-based aqueous coatings are among the most commonly used coatings available today and provide good protection from fingerprints and other blemishes. Like varnishes, aqueous coatings are applied inline on the press, but they are shinier and smoother than varnish, have higher abrasion and rub resistance, are less likely to yellow, and are more environmentally friendly. Aqueous coatings dry faster than varnishes too, which means faster turnaround times.

-

UV Coatings

Extremely high gloss UV, or ultraviolet, coatings offer more protection than either varnish or aqueous coatings. UV coatings are applied as a liquid, using a roller, screen, or blanket, and then exposed to ultraviolet light to polymerize and harden the coating, with zero emissions. The coatings can either be applied across the entire page or, while lacking the precision of varnish, on a spot basis. The coatings are available in a high gloss as well as matte, satin, and a wide variety of specialty finishes.

-

Varnishes

Varnish is a thin-protective layer that is applied to a printed sheet for protection or appearance. This coating has two options: UV- or aqueous-based. For packaging purposes, varnishes are essentially clear ink that can be dull, satin, matte, or glossy.

-

Soft Touch

A soft-touch finish is a protective finish that has a matte effect. Soft Touch has a velvet-like texture and that creates a softer look and feel to printed materials.

Specialty Finishing Options

-

Die Cutting

A method of using sharp steel ruled stamps or rollers to cut various shapes i.e. labels, boxes, image shapes, either post press or in line. The process of cutting paper in a shape or design by the use of a wooden die or block in which are positioned steel rules in the shape of the desired pattern.

-

Rivets & Eyelits

Rivets and eyelets are utilized in printing to reinforce holes punched through a substrate. Some can be utilized as a hinge allowing multiple pieces to move freely and fan out around it. They typically come in colors such as gold and silver.

-

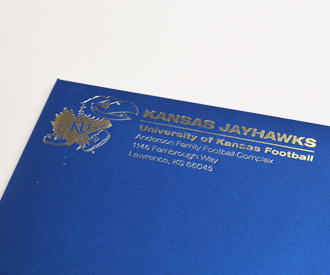

Foil Stamping

A process for printing from images engraved into copper or steel places and stamping with foil to give a metallic look.

-

Embossing

To raise in relief a design or letters already printed on card stock or heavy paper by an un-inked block or die. In rubber and plastic plate making the process is usually done by heat.

-

Lamination

Use of material such as plastic to press over the print product to provide more strength and stability.

-

Perforation

Punching small holes or slits in a sheet of paper or cardboard to facilitate tearing along a desired line.

-

Round Corners

The edges of the product are rounded.

-

Tabs

Get custom divider tabs for better organization for your binders.

-

Custom Folding

We offer custom folding options such as fan folds, right-angle folds, and more.

-

Drill Hole

Drilling of holes into paper for ring or comb binding.